Substances which at room temperature retain their ferromagnetic property for a long period of time are called permanent magnets. Permanent magnets can be made in a variety of ways. One can hold an iron rod in the north-south direction and hammer it repeatedly.

The hysteresis curve (Fig.) allows us to select suitable materials for permanent magnets. The material should have high retentivity so that the magnet is strong and high coercivity so that the magnetization is not erased by stray magnetic fields, temperature fluctuations or minor mechanical damage. Further, the material should have a high permeability. Steel is one-favoured choice. It has a slightly smaller retentivity than soft iron but this is outweighed by the much smaller coercivity of soft iron.

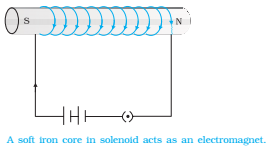

Core of electromagnets are made of ferromagnetic materials which have high permeability and low retentivity. Soft iron is a suitable material for electromagnets. On placing a soft iron rod in a solenoid and passing a current, we increase the magnetism of the solenoid by a thousand fold. When we switch off the solenoid current, the magnetism is effectively switched off since the soft iron core has a low retentivity. The arrangement is shown in Fig.

Electromagnets are used in electric bells, loudspeakers and telephone diaphragms. Giant electromagnets are used in cranes to lift machinery, and bulk quantities of iron and steel.